The operating concept for the Musashi-Koyama module set was to have

it function either as a double or single track module, be in line with

other modules that are either double or single track, or be an end of

line terminal. When connected to a single track modules, it could be

used as a passing siding. Cross overs and power routing was controlled

by a single switch on the roof of one of the taller buildings. There was a mode switch under the modules which bridged the inputs to the two tracks together when running in the single track mode.

The drawing above is a very basic representation of the tracks and controls how they were originally set up. While it had preformed quite well several times as a terminal end module, the first time we attempted to use it in line between other modules did not work out so well. I had not considered that while the main line might be single track, the second track may extend to an adjoining module and that power may be routed by a turnout on that module. Another issue was that in this type of setup there was no way to control the cross overs independently.

Here is another drawing showing the basic representation of how the track circuits on the module are now controlled. Each crossover now has it's own control. Also one rail on each track was isolated and their connections are made through another pair of switches so either track next to the station platform can be turned off.

This photo shows the new gaps cut in the rails at one end of the platform. Most of our trains have electrical pickup in all units meaning a train needs to stop within the platform track limits to avoid bridging the gap. I installed some black post to make these limits more visible to operators.

The 4 new toggle switches are located on the roof of the same building as the original single switch was. This paper building has a rigid structure under it to support the switches and also houses 2 tortoise motors.

This is what an operator standing behind the sky board inside the layout will see looking down at the roof of the building. The empty square hole was where the original switch was.

I use 16 pin AMP connectors to make the all connections between the

modules. I had two pairs of wires left unused so I used one pair to

carry the switched platform track over to the other module.

The mode switches used to select single or

double track modes was no longer needed and was removed. In it's place I

installed RCA jacks which are the AsiaNrail standard connection for

turnout power. I don't use this power so these will just carry it thru

the module using the last spare pair of wires on the 16 pin AMP

connector.

Another modification made was to create a switchable isolation gap somewhere within the module per AsiaNrail standards.

The best place to do this was at the gap between the middle and small module as rails already have a gap there and I only needed to place some switches in the connection between the modules.

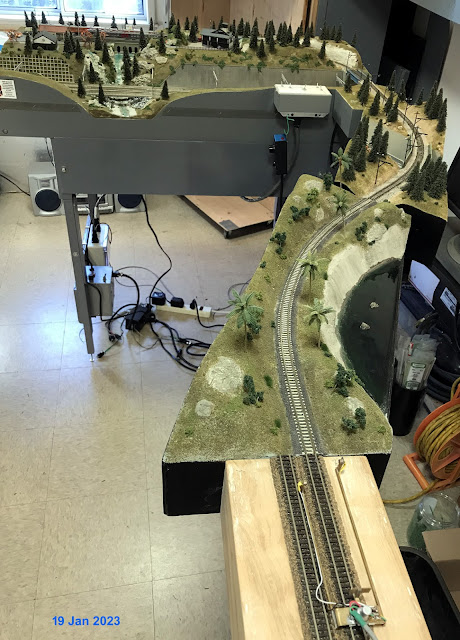

I have been testing the heck out of this and all seems good at this point so it's now on to more scenery.